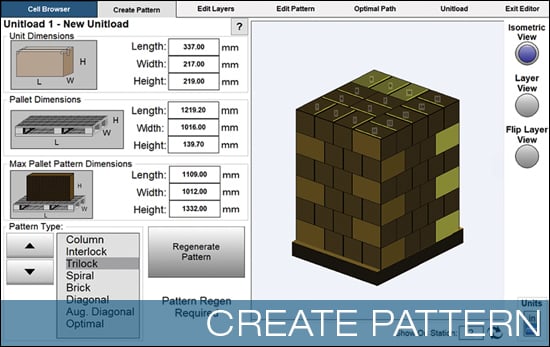

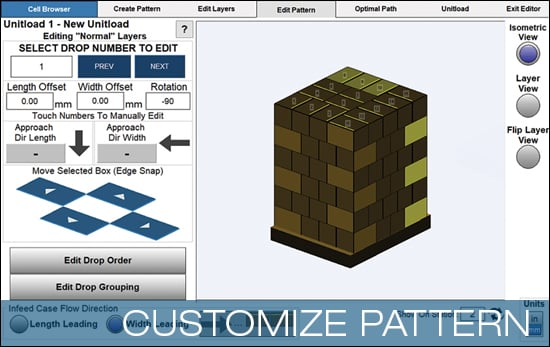

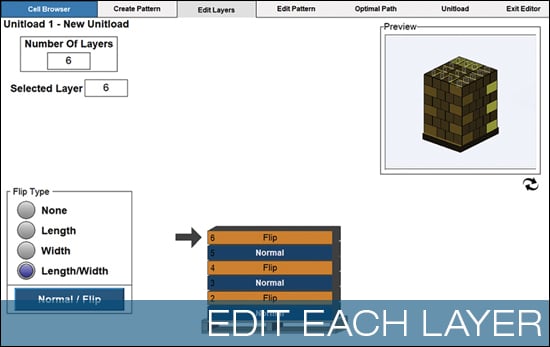

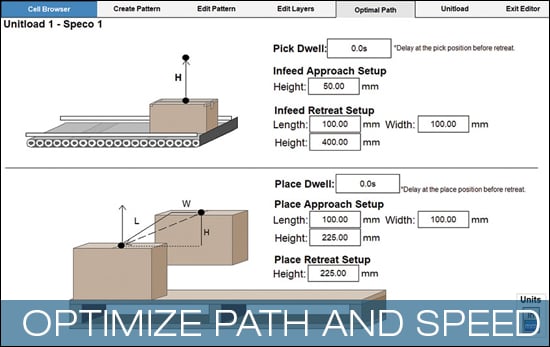

OptiStak, created by Schneider, is a seamless and simple palletizing software solution. This software meets the production requirements of virtually any industry or product. Your operators can change patterns on the fly, optimize pallet configurations quickly, and avoid changeover delays—directly from the HMI. Optimize ease of release and time to market for your new products with OptiStak.

We chose Schneider because they have an OptiStak software that they use to create the recipes of the layers which is very user-friendly. Our staff likes the way it works, takes a few minutes to make a change, a few hours to make a new recipe.

Emilio Lemus, Automation Manager Tasteful Selections

How This Pallet Generation Software Helped One Growing Business Get Bigger »

With more than 50 years of industry problem solving in end-of-line automation, Schneider Packaging Equipment Company, Inc. is a leading manufacturer of case packing and robotic palletizing solutions. Headquartered in Upstate New York, we design state-of-the-art machinery for customers in industries such as food and beverage, dairy, pharmaceutical, personal care, plastics, and paper.

© 2021 Schneider Packaging Equipment Company, Inc. | Privacy Policy